The treatment plants are produced in two variants:

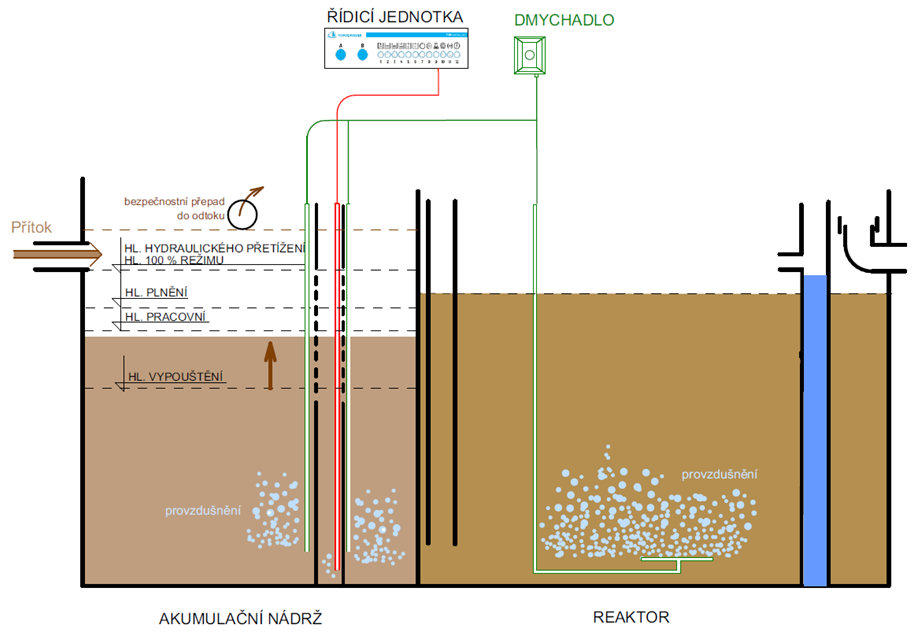

1. Filling the accumulation

Wastewater flows into the storage tank and the water level in the storage tank rises from the discharge level to the filling level. During this time, the bioreactor is aerated and the wastewater is biologically treated. At the same time, the accumulation is aerated and mixed.

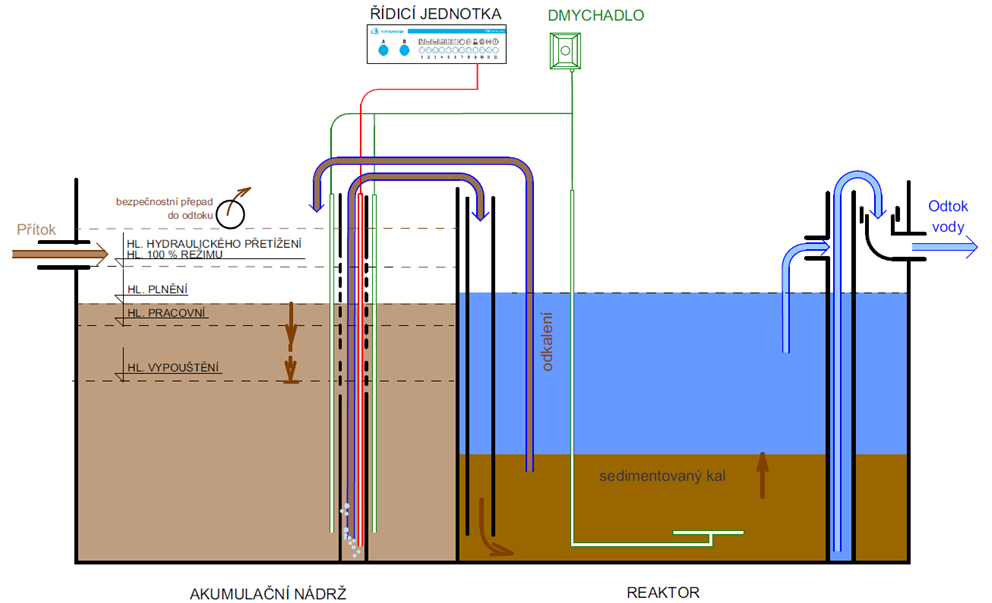

2. Sedimentation

When the filling level is reached, the blower is switched off for a set period of time and the sludge in the accumulation and in the bioreactor sediments at the bottom.

3. Discharge

The pre-treated effluent, no longer free of coarse impurities, is pumped into the sludge layer at the bottom of the bioreactor, thereby pushing the treated water to the surface of the bioreactor. From there, the treated water is pumped from the subsurface layer to the outlet. When the water level in the accumulation drops to the discharge level, the filling phase is resumed.